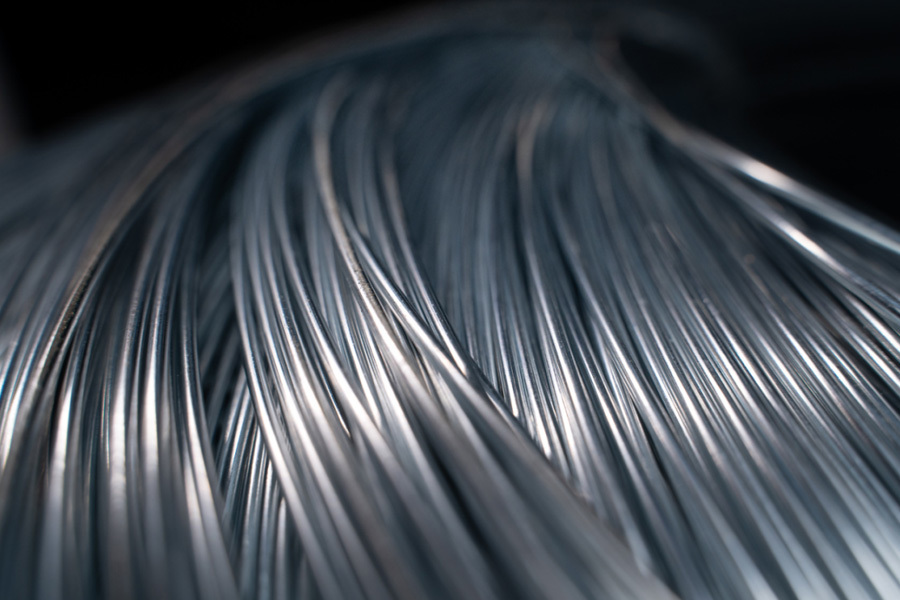

Pulp Baling Wire

Beyond Imagination: Product Longevity

1-Anti-corrosion capability, that is, the adhesion of the zinc layer and related coatings on the wire;

2-Minimal impact from aging, meaning changes in the mechanical properties of the wire due to the aging of steel products.

Broad Wire employs the latest technology, which, by altering the arrangement of crystals, significantly reduces the impact of aging on products, even approaching the minimum. This ensures that the performance of steel products remains stable in terms of mechanical properties for an extended period, thereby enhancing the safety and reliability of the product when in use.

Pulp Packaging Solution-ist

Broad Wire is the first and the only company in the world to supply and serve pulp mills across all regions from a singular production base. We are also the unique global production base that employs eco-friendly heat treatment processes for manufacturing pulp baling wire. Furthermore, Broad Wire is the only manufacturer with the capability to perform 100% usability (knotting) tests on every wire.

Empowered by Technology, Rooted in Quality

Over our 15-year tenure in the industry, we have consistently maintained a record of zero returns, establishing ourselves as a trusted strategic partner for many of the world’s leading forestry pulp and paper conglomerates.

Over the past decade and more, Broad Wire has not only filled the product void in China's commodity pulp logistics industry but has also integrated Canada's cooperative production experience and technology. By adopting the most advanced production techniques from Europe and North America, Broad Wire continually evolves, innovates, and refines its proprietary technology and processes with a global industry vision.

One Factory, Serving the World

In China's sector, Broad Wire commands a market share exceeding 75%. Simultaneously, in Southeast Asia, we cater to over 50% of the market, offering both premium products and corresponding services. Currently, Broad Wire has forged strategic partnerships with internationally renowned enterprises, including: groups owning 53 factories in China and dozens worldwide; the two largest pulp conglomerates in Southeast Asia with dozens of factories in Southeast Asia, South America, and China; the industry titan in South America, the largest commodity pulp producer globally; a Europe-based bio-enterprise conglomerate with factories in 13 countries and regions rooted in forestry; and a Chilean conglomerate with over 20 timber and forestry product manufacturers globally. Broad Wire proudly stands as one of their primary service providers and suppliers.

Product parameters

| Product:Pulp Baling Wire |

| Specification:1.86mm-4.2mm |

| Material:High Carbon Steel |

| Standard:YB/T 4296-2021 《Galvanized Wire for Pulp Baling》 |

Application

Transportation for Packed Market Pulp and Wasted Paper

中文版

中文版 English

English

Lead-less Green Craft

Lead-less Green Craft